What role does each part of the coffee supply chain play at origin?

How does the production side of the coffee supply chain work? And what value does it play in the delivery of coffee?

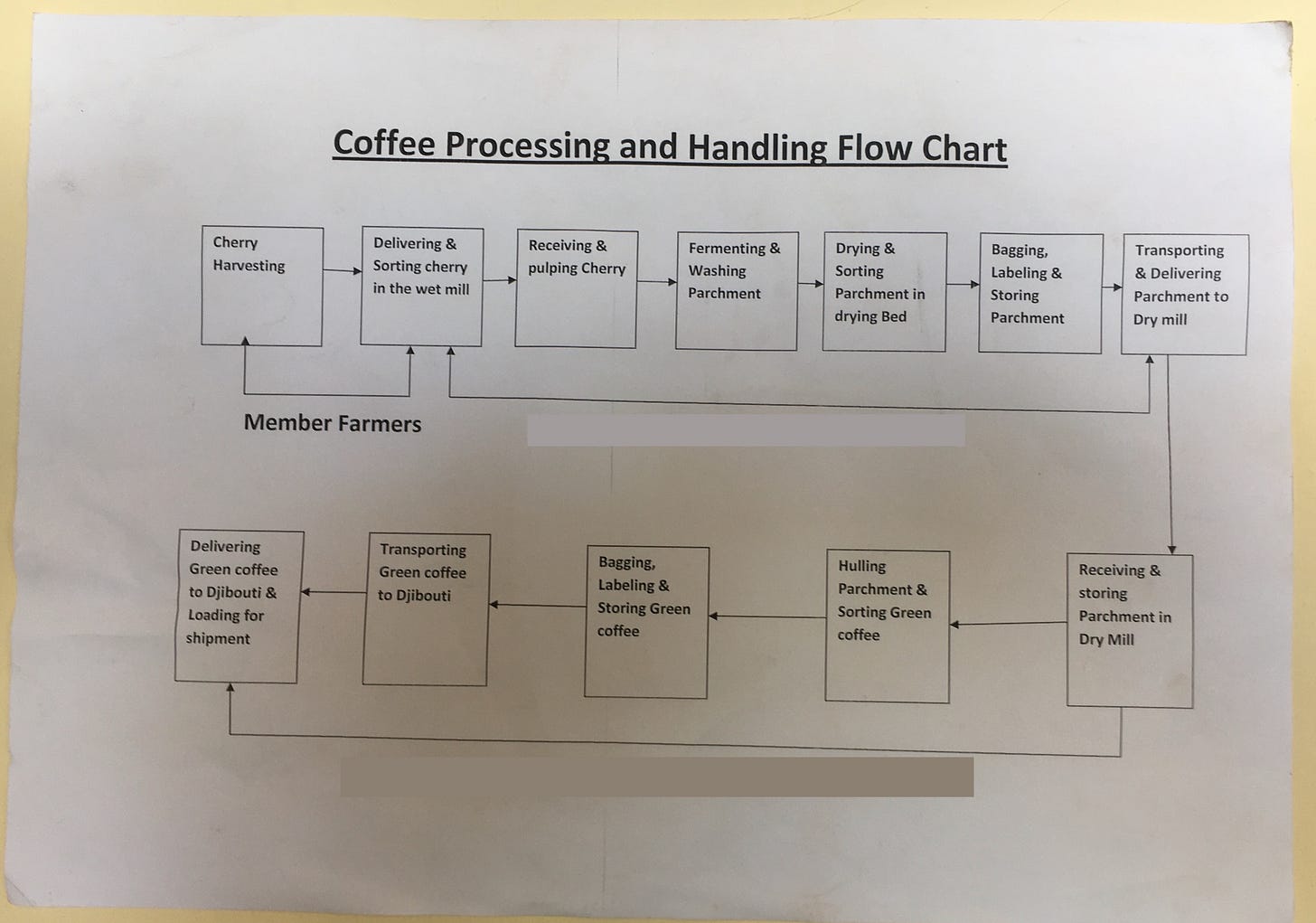

This is the second of four 4 posts examining the coffee supply chain. In this part I take a look at how the supply chain works at origin; showing how coffee gets from the field to the port.

In the first post in this series I looked at direct trade as a movement aiming to help farmers receive a more a sustainable income from their coffee production. I thought it would show the realities of such as approach and how complex the coffee supply chain really is.

So this time, let’s look in a bit more detail at what happens at origin as coffee makes its way from the farm and is prepared for export.

Whilst each origin has its own rules and variations, in general there are many common parts and processes that are common across the board.

So let’s take a look at how it works.

Who are coffee producers?

Coffee producers is a broad term covering many different part of the supply chain. In its broadest sense, it means ‘farmers’, but it can also applied to organisations collecting and processing coffee cherries and green coffee beans from a variety of sources who in turn create a product ready for export.

Some producers will be farmers who also own wet and dry mills. And in some cases may also be exporters. Although exporters are not generally involved in the logistics themselves; they will work with agents who organise the transporting of coffee to port.

Smallholders and cooperatives

Smallholders represent 80% of those who farm coffee. These may include people making a living by working a small patch of land, through to those who manage developed farming operations or farm estates made up of several farms.

Smallholder farmers produce the “cherries” (the fruit containing the bean) and drop them at washing stations where they are processed and prepared for the wet mill. The wet mill may be operated by a co-operative or it may run by a larger coffee producer who puts all the coffee together for processing to create a larger blended lot.

Where a farmer has a more sophisticated operation or is part of a co-op, the coffee will be put together and sold under the banner of the co-op or farm. Quite often this will be considered to be single origin coffee.

The farmer will receive a (cherry) price for what they have produced and this, in many cases is their income for the entire year.

Whilst they are beholden to the market, the cherry price is what matters to them and in some cases these farmers will never drink their own coffee. If the market prices are consistently down they may be tempted to find alternative, more lucrative crops to grow. It is not unknown for them to rip up their coffee plants and replace them with something like chat, in the hope of generating more income.

To prevent this, responsible members of the supply chain, will provide help to improve the outcomes of coffee production for these smallholders.

Coffee preparation & processing

If a farmer owns their own wet mill, they manage the process completely in-house. They may also add in cherries from other small producers, either on contract or as a purchase for their own production output.

Cooperatives will usually have their own wet mills, and account for where each lot comes from, and pay smallholders accordingly. Collaborating with a co-operative benefits smallholders who can’t afford to own their own infrastructure not only in terms of production but as a means of accessing the market.

The way the coffee is processed through the wet mills will determine the profile of the coffee itself. Many commercial coffees tend to be washed or natural coffees. There are also opportunities for further differentiation in the market. There is a also growth in a third options which produces honeyed coffee which is part washed and part natural.

The greatest amount of innovation comes with the microlot competition style coffees often featured in coffee auctions and barista competitions. These coffees tend to be unique and produced in short in supply and consequently command very high prices. They also server a purpose of discovery and reputation, helping connect them to new buyers in new markets.

Coffee ready for export

Coffee is at this point stored as parchment, which maintains it freshness. When coffee is contracted it will be hulled, bagged and graded according to origin based standards and made ready for export in a dry mill. the exporter will also mark the bags with the importers logo as well as their own.

From this point on the exporter will liaise with logistics agents and organise the forwarding of containers to port.

All of these steps add up to a complex process, involving management and supervision at every step. While one company or organisation can own or operate many parts of the chain, they do rely on each other and on a range of different skills. Each of these adding value but also cost to the production process. And of course everyone involved expects to cover their owns and turn a profit for their efforts.

In the next post we will look at what happens to the coffee once it arrives at it’s destination ready for import and develop our understanding who the value added as the coffee is prepared for sale.